Industrial-Grade PEM Hydrogen Generator

WH-4L

Bright Annealing for Stainless Steel and Copper

Achieve better surface finish and internal structure by replacing bottled hydrogen with stable, high-purity on-site hydrogen.

Hydrogen Atmosphere Heat Treatment

Used in sintering, deoxidation, and reduction processes to enhance product consistency and reduce surface oxidation.

Brazing and Precision Welding

Supports micro-welding and precision flame operations with consistent hydrogen flow, integrated into automated production lines.

Special Alloys and 3D Printed Metals Post-Treatment

Enables controlled reduction atmospheres for high-performance materials and additive manufacturing components.

Main Application Scenarios

🔩 Metal Annealing and Heat Treatment

Used for reduction annealing of metals such as stainless steel and copper. Replaces bottled hydrogen to improve surface finish and structural properties.

🧪 Fine Chemicals and Pharmaceutical Industry

Supports reduction reactions, hydrogenation processes, and protective atmospheres for pilot-scale and continuous experiments.

💎 Glass and Quartz Flame Processing

Provides a high-temperature, clean flame gas source for precision polishing and cutting of specialty glass and quartz.

🔬 Laboratories and Pilot-Scale Platforms

Delivers stable and continuous hydrogen supply for medium-flow applications such as gas chromatography, chemical synthesis, and fuel cell testing.

🔧 Industrial Micro-Welding and Automation Integration

Supplies reliable hydrogen for micro-welding robots, packaging lines, and automated inspection systems.

Key Features

🔹 Hydrogen Output: 2–4 L/min – Designed for small to medium-scale production lines or lab-scale process validation.

🔹 Purity ≥99.99% – Suitable for direct industrial use without further purification.

🔹 24/7 Continuous Operation – Built for high-reliability, industrial-grade use.

🔹 On-Demand Generation – No storage or transport risks; hydrogen is produced as needed.

🔹 Clean and Sustainable – Only water and electricity required; no CO₂ emissions.

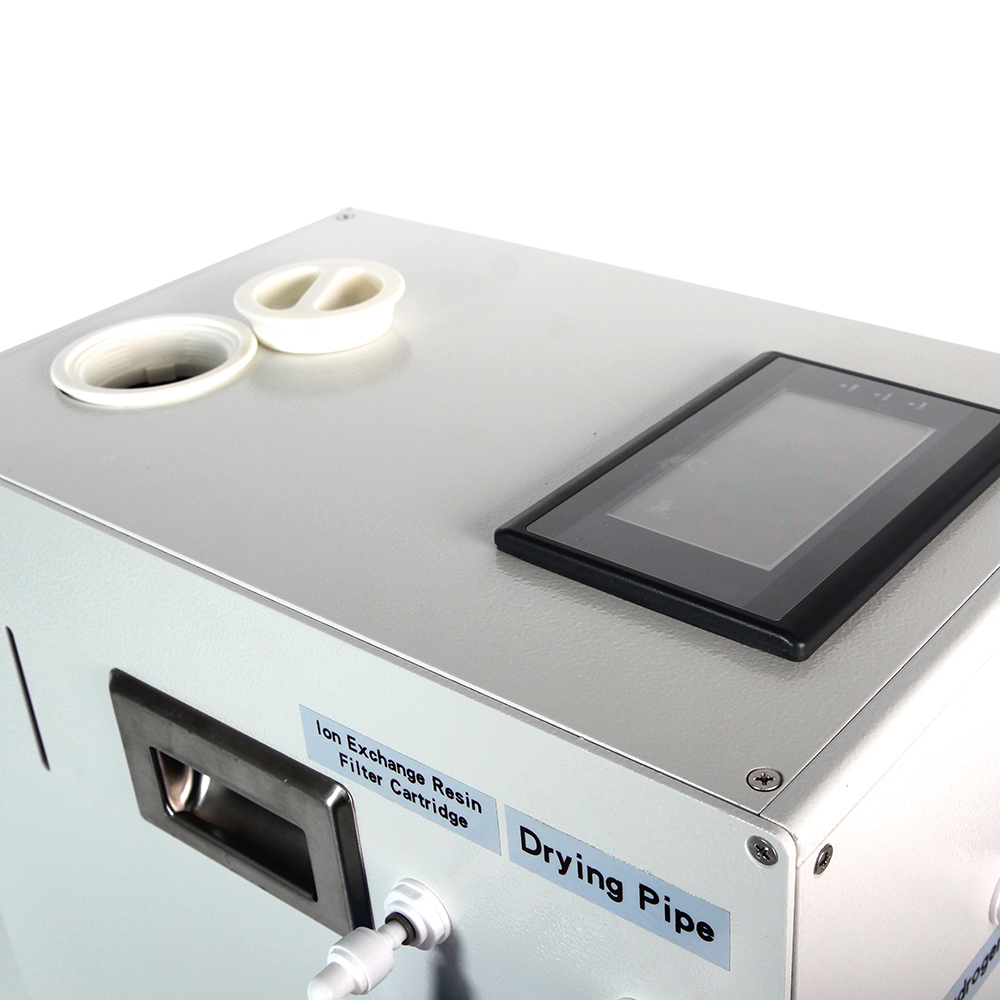

🔹 Easy Integration – PLC control and remote monitoring options for system automation.

Technical Specifications (Customizable)

| Parameter | Specification |

|---|---|

| Hydrogen Output | 2000–4000 ml/min (customizable) |

| Hydrogen Purity | ≥99.99% (up to 99.999%) |

| Output Pressure | 0.3–0.6 MPa (adjustable) |

| Power Supply | AC 220V/380V, 50Hz/60Hz |

| Cooling | Air or water cooling |

| Control System | PLC + optional remote monitoring |

| Dimensions | Table-top or cabinet design based on output level |

We provide customized hydrogen solutions tailored for metal processing, helping you create a safer, more efficient, and greener production environment.

The Miracle of Hydrogen